Pro/ENGINEER CAD-Methodology

Customer: OEM / Passenger and freight elevators

A globally operating manufacturer for passenger and freight elevators requested support for the realisation of an efficient product development to continuously increase product complexity and diversity of variants.

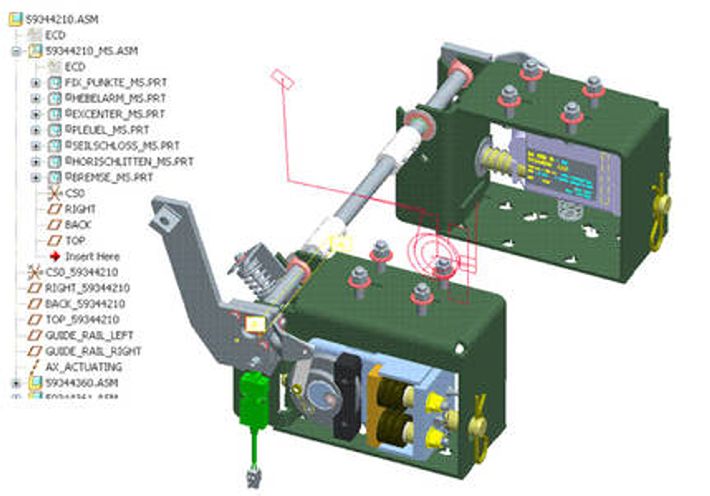

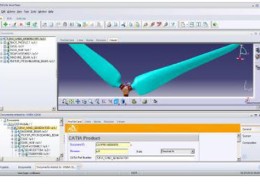

Main target of the project was to define and implement a CAD-methodology which supports the product development process and efficiently provides all relevant data for downstream processes and applications.

All brand names, product names and abbreviations are the property of their respective companies.

Project Definition

A globally operating manufacturer for passenger and freight elevators requested support for the realisation of an efficient product development to continuously increase product complexity and diversity of variants. Main target of the project was to define and implement a CAD-methodology which supports the product development process and efficiently provides all relevant data for downstream processes and applications.

Realisation

The realisation of the project was splitted in the phase setup (developing of a project manual), analysis, definition and implementation. Step one contained interviews of the employees and users – hence the as-is status was engaged and suggestions for improving CAD methodologies have been developed. Problem statements and targets had been defined in several workshops.

An as-is analysis took place with reference to CAD-methodology and CAD processes, even a target concept has been worked out.

This implied:

- Definition of measures to improve the workflow (system-independent)

- Definition of the specification catalogue

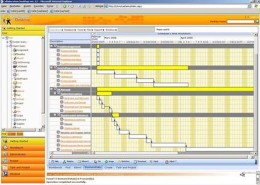

- Definition of target applications (CAD-data management, Document management, ERP-interface etc.)

- Attainment of a consistent understanding for all relevant parties

RLE‘s Competence

CAD-methodology development and the user support have been provided by RLE-employees based on many years of PLM experience, in particular Pro/ENGINEER.

Value for the customer

The customer was enabled to develop a complete 3D product model including all product lifecycle data. Due to the definition and documentation of the 3D-CAD-modelling methodology, analysis- and simulation functions could be increased – this led to time and cost savings. In addition an efficient support for roll-out and deployment of the CAD-methodology has been provided to the customer, this even led to a skill improvement of the key-users.